What Are the Types of Thermoplastic Sheets?

Thermoplastic sheets are integral components in a wide array of industries, offering versatility, durability, and adaptability to meet diverse application needs. Derived from polymers that can be repeatedly softened by heating and hardened by cooling, thermoplastic sheets play a crucial role in modern manufacturing processes.

In various industries such as automotive, construction, packaging, healthcare, and electronics, thermoplastic sheets serve as indispensable materials for fabrication, insulation, protection, and structural support. Their ability to be molded into complex shapes, along with their lightweight nature and resistance to corrosion and chemicals, makes them highly sought after in engineering and design applications.

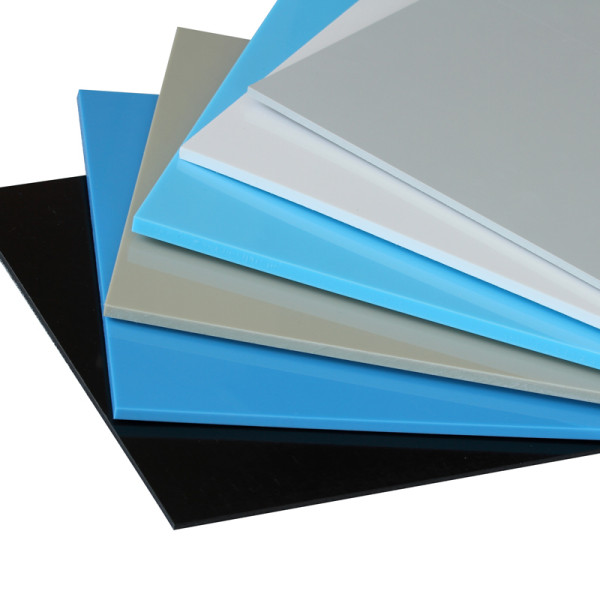

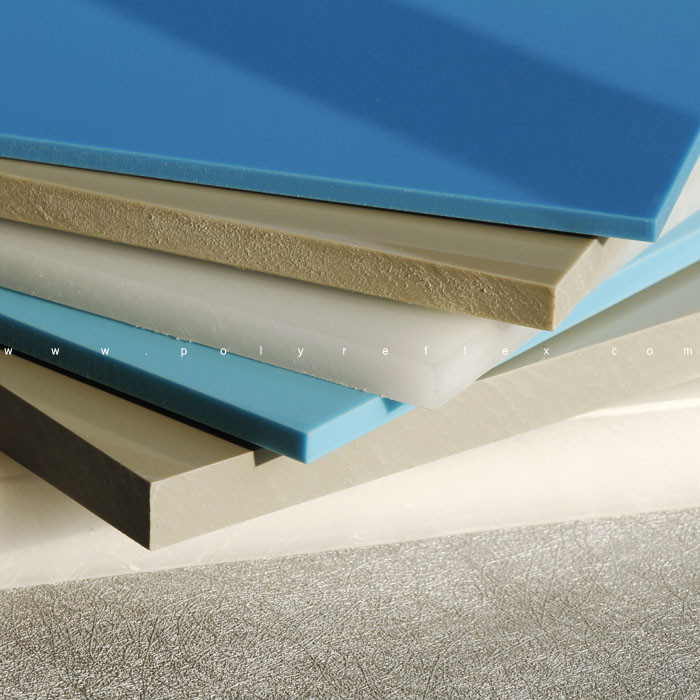

In this article, we will delve into the types of thermoplastic sheets that are commonly used in industries worldwide. From ABS to HDPE, PVC to PP, and TPO, each type offers unique properties and advantages suited to specific applications. By understanding the characteristics and applications of these thermoplastic sheets, readers can make informed decisions regarding material selection for their projects, ensuring optimal performance and efficiency.

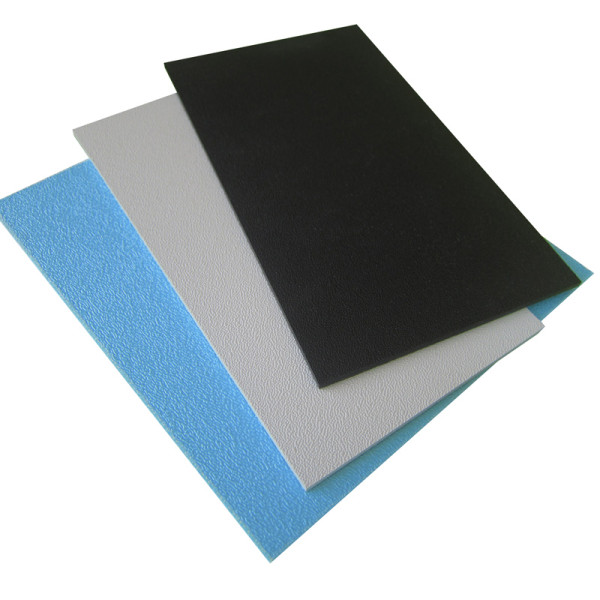

Polyreflex ABS sheet is a high impace resistant plastic sheet that is easy to thermal form, CNC cut and laser cut.

Elastic material, harmless, possess good hardness, flex fatigue and impact resistance, suitable for injection & vacuum forming

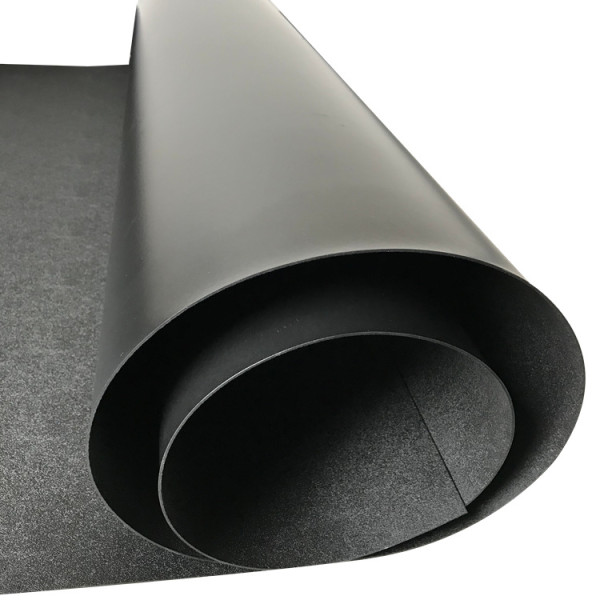

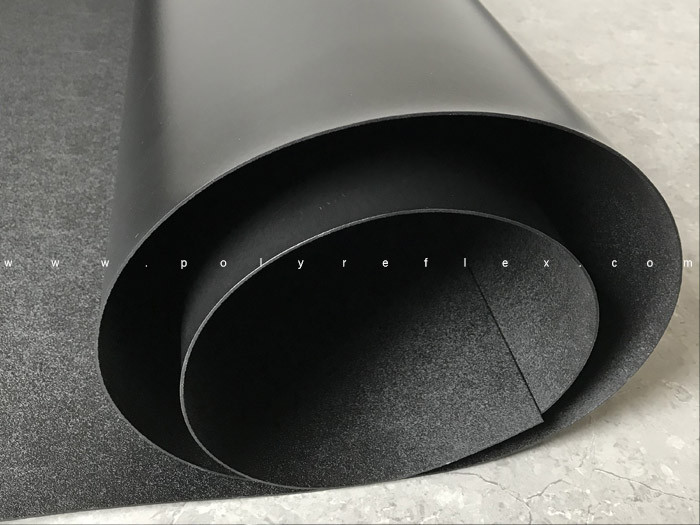

Polyreflex supplies HDPE sheet with high impact strength, high abrasion resistance, custom machining and assembly is available.

Polyreflex offers high quality polypropylene sheets with different properties, as well as custom processing of plastic sheets.

If you don't have time to read through these detailed textual analyses, we have created a comparison table for these thermoplastic materials at the bottom of the article for your convenience.

Understanding ABS Sheets

ABS (Acrylonitrile Butadiene Styrene) sheets are a type of thermoplastic material known for their exceptional combination of properties, making them versatile and widely used across various industries.

1. Explanation of ABS Sheets

ABS sheets are composed of a blend of three distinct monomers: acrylonitrile, butadiene, and styrene. This unique combination results in a thermoplastic material with excellent mechanical properties, chemical resistance, and dimensional stability. ABS sheets are typically manufactured through a process of extrusion or injection molding, allowing for precise control over their thickness and dimensions.

2. Overview of ABS Sheet Properties

ABS sheets exhibit remarkable durability, making them resistant to abrasion, impact, and wear over time. Their high tensile strength and toughness make them suitable for demanding applications where mechanical stress is a concern. Additionally, ABS sheets offer good heat resistance, retaining their structural integrity even at elevated temperatures. Furthermore, ABS sheets can be easily machined, drilled, and fabricated, allowing for intricate designs and customized solutions.

3. Common Applications of ABS Sheets

ABS sheets find widespread use across a diverse range of industries due to their excellent properties and versatility. In the automotive sector, ABS sheets are employed in interior and exterior components, such as dashboard panels, trim pieces, and automotive body parts, thanks to their impact resistance and aesthetic appeal. In the electronics industry, ABS sheets are utilized in the fabrication of casings, enclosures, and housing for electronic devices due to their electrical insulation properties and ability to withstand harsh operating environments. Moreover, ABS sheets are commonly used in consumer goods, including luggage, toys, and appliances, where their durability, impact resistance, and ease of processing make them an ideal choice for mass production applications.

In summary, ABS sheets stand out as a reliable and versatile thermoplastic material, offering a unique combination of properties that make them suitable for a wide range of applications across industries such as automotive, electronics, and consumer goods. Their durability, impact resistance, and heat resistance make them a preferred choice for manufacturers seeking high-performance materials for their products.

Delving into HDPE Sheets

HDPE (High-Density Polyethylene) sheets represent a versatile and widely used thermoplastic material renowned for its exceptional properties and diverse applications across various industries.

1. Introduction to HDPE Sheets

HDPE sheets are composed of high-density polyethylene polymers, characterized by a tightly packed molecular structure that imparts excellent strength, durability, and chemical resistance. This unique composition allows HDPE sheets to maintain their structural integrity even under harsh environmental conditions, making them highly sought after in numerous industries.

2. Description of HDPE Sheet Properties

HDPE sheets boast a range of desirable properties that make them suitable for a wide array of applications. Firstly, their flexibility sets them apart, allowing for easy fabrication, bending, and molding to meet specific design requirements. Additionally, HDPE sheets exhibit exceptional chemical resistance, making them impervious to corrosive substances, acids, and alkalis. Moreover, HDPE is known for its environmental friendliness, as it is recyclable and can be repurposed for various applications, contributing to sustainable manufacturing practices.

3. Applications of HDPE Sheets

HDPE sheets find extensive use across diverse industries owing to their versatile properties and suitability for various applications:

- Packaging: HDPE sheets are commonly utilized in packaging applications due to their excellent strength, flexibility, and chemical resistance. They are used for manufacturing bottles, containers, and packaging films for food, beverages, pharmaceuticals, and personal care products.

- Construction: In the construction industry, HDPE sheets serve multiple purposes, including as liners for ponds, reservoirs, and landfills due to their impermeability and resistance to moisture. Additionally, HDPE sheets are used in geotextiles, pipes, and fittings for infrastructure projects, thanks to their durability and longevity.

- Agriculture: HDPE sheets play a vital role in modern agriculture, where they are employed as greenhouse coverings, liners for irrigation systems, and protective barriers for crop cultivation. Their impermeability, chemical resistance, and durability contribute to improved crop yields and resource conservation.

- Aquaculture: In the aquaculture industry, HDPE sheets are utilized for constructing fish tanks, floating cages, and containment systems due to their resistance to corrosion, chemicals, and UV radiation. HDPE's durability and low maintenance requirements make it an ideal material for creating sustainable aquaculture environments.

In summary, HDPE sheets stand out as a versatile and indispensable material in various industries, offering a combination of flexibility, chemical resistance, and environmental sustainability. Their widespread applications in packaging, construction, agriculture, and aquaculture underscore their importance in modern manufacturing and infrastructure development.

Exploring PVC Sheets

PVC (Polyvinyl Chloride) sheets are a widely used thermoplastic material known for their versatility, durability, and ease of fabrication. Let's delve into the characteristics, properties, and common applications of PVC sheets:

1. Overview of PVC Sheets

PVC sheets are manufactured from polyvinyl chloride resin, which is synthesized through the polymerization of vinyl chloride monomers. This process results in a thermoplastic material that can be easily molded, shaped, and extruded into sheets of various sizes and thicknesses. PVC sheets are available in both rigid and flexible forms, offering manufacturers a wide range of options to suit their specific application requirements.

2. Discussion of PVC Sheet Properties

PVC sheets exhibit several key properties that make them highly desirable for a multitude of applications. Firstly, PVC is renowned for its rigidity, providing excellent structural support and stability in various settings. Additionally, PVC sheets boast exceptional chemical resistance, making them impervious to corrosion, acids, and alkalis. Moreover, PVC is inherently fire retardant, meaning it has a low risk of ignition and does not support combustion, making it suitable for applications where fire safety is a concern.

3. Common Uses of PVC Sheets

PVC sheets find widespread use across diverse industries due to their unique properties and versatility. Some common applications of PVC sheets include:

- Construction: PVC sheets are extensively used in the construction industry for various purposes, including cladding, roofing, and insulation. Their durability, weather resistance, and ease of installation make them ideal for exterior applications where protection from the elements is essential.

- Signage: PVC sheets are popularly used for signage and display applications due to their smooth surface finish, excellent printability, and lightweight nature. They are often employed in advertising boards, shop signage, and exhibition displays, providing a durable and cost-effective solution for promoting brands and messages.

- Healthcare: In the healthcare industry, PVC sheets are utilized for manufacturing medical equipment, devices, and components due to their biocompatibility, sterilizability, and resistance to chemicals. They are commonly used for constructing medical tubing, IV bags, and surgical instruments, ensuring patient safety and hygiene.

In summary, PVC sheets are a versatile and widely used thermoplastic material with a multitude of applications across industries such as construction, signage, and healthcare. Their rigidity, chemical resistance, and fire retardancy make them a preferred choice for manufacturers seeking durable and reliable materials for their products and projects.

Unveiling PP Sheets

PP (Polypropylene) sheets represent a versatile and widely utilized thermoplastic material appreciated for its exceptional properties and diverse applications across various industries.

1. Introduction to PP Sheets

PP sheets are crafted from polypropylene resin, which is formed through the polymerization of propylene monomers. This manufacturing process results in a thermoplastic material renowned for its lightweight nature, flexibility, and excellent chemical resistance. PP sheets are available in various grades and thicknesses to accommodate a wide range of applications.

2. Description of PP Sheet Properties

PP sheets boast a multitude of advantageous properties that make them highly sought after in numerous industries. Firstly, their lightweight nature sets them apart, making them easy to handle, transport, and fabricate. Additionally, PP sheets exhibit remarkable chemical resistance, rendering them impervious to acids, alkalis, and solvents. Furthermore, PP sheets are inherently moisture-resistant, making them suitable for use in humid or wet environments without degradation.

3. Applications of PP Sheets

PP sheets find extensive use across diverse industries owing to their versatile properties and suitability for various applications:

- Packaging: PP sheets are commonly utilized in the packaging industry for manufacturing containers, trays, and packaging films. Their lightweight nature, durability, and moisture resistance make them ideal for protecting and preserving a wide range of products, including food, beverages, and pharmaceuticals.

- Automotive: In the automotive sector, PP sheets are employed in various interior and exterior components, such as door panels, dashboard trim, and bumper fascia. Their lightweight nature, impact resistance, and ability to withstand harsh environmental conditions make them ideal for automotive applications.

- Medical: PP sheets are also utilized in the medical industry for manufacturing medical devices, laboratory equipment, and disposable medical supplies. Their biocompatibility, sterilizability, and chemical resistance make them suitable for use in healthcare settings where hygiene and safety are paramount.

In summary, PP sheets stand out as a versatile and indispensable material in various industries, offering a combination of lightweight, chemical resistance, and moisture resistance. Their widespread applications in packaging, automotive, and medical sectors underscore their importance in modern manufacturing and product development.

Understanding TPO Sheets

TPO (Thermoplastic Olefin) sheets are a versatile class of thermoplastic materials that have gained significant popularity for their exceptional properties and wide-ranging applications across various industries.

1. Introduction to TPO Sheets

TPO sheets are composed of a blend of polypropylene (PP) and ethylene-propylene rubber (EPR) polymers, resulting in a thermoplastic material known for its excellent balance of properties. TPO sheets are manufactured through a process of extrusion or calendering, allowing for the production of sheets with varying thicknesses and dimensions to suit specific application requirements.

2. Overview of TPO Sheet Properties

TPO sheets exhibit several key properties that make them highly desirable for a multitude of applications. Firstly, their flexibility sets them apart, allowing for easy bending, shaping, and molding into various forms without compromising structural integrity. Additionally, TPO sheets boast exceptional weather resistance, making them resistant to UV radiation, moisture, and extreme temperatures, ensuring long-term durability and performance in outdoor environments. Moreover, TPO sheets are recyclable, making them an environmentally friendly choice for sustainable manufacturing practices.

3. Applications of TPO Sheets

TPO sheets find extensive use across diverse industries owing to their versatile properties and suitability for various applications:

- Automotive: In the automotive industry, TPO sheets are commonly used for manufacturing interior and exterior components, such as bumper covers, door panels, trim pieces, and floor mats. Their flexibility, impact resistance, and weatherability make them ideal for automotive applications where durability and aesthetics are paramount.

- Roofing: TPO sheets are widely utilized in the construction industry for roofing membranes and waterproofing systems. Their excellent weather resistance, flexibility, and heat-weldability make them an ideal choice for roofing applications, providing protection against the elements and ensuring long-term durability.

- Other Outdoor Applications: TPO sheets are also employed in a variety of other outdoor applications, including signage, agricultural equipment, and recreational vehicles. Their weather resistance, flexibility, and ease of fabrication make them suitable for outdoor environments where exposure to UV radiation, moisture, and temperature fluctuations is common.

In summary, TPO sheets represent a versatile and durable thermoplastic material with a wide range of applications across industries such as automotive, construction, and outdoor recreation. Their unique combination of flexibility, weather resistance, and recyclability makes them a preferred choice for manufacturers seeking high-performance materials for their products and projects.

Comparing and Contrasting Thermoplastic Sheets

Thermoplastic sheets, including ABS, HDPE, PVC, PP, and TPO, each offer unique properties and advantages suited to specific applications. Let's compare and contrast these thermoplastic sheets based on their properties, applications, and suitability for different industries:

|

Material

|

Properties

|

Applications

|

|

ABS Sheets

|

ABS sheets exhibit excellent impact resistance, durability, and heat resistance. They are also easily machinable and offer good electrical insulation properties.

|

ABS sheets are commonly used in automotive, electronics, and consumer goods industries for components such as dashboard panels, casings, and toys.

|

HDPE Sheets | HDPE sheets are known for their flexibility, chemical resistance, and environmental friendliness. They offer excellent durability and are impervious to moisture and chemicals. | HDPE sheets find applications in packaging, construction, agriculture, and aquaculture industries due to their versatility and resilience. |

PVC Sheets | PVC sheets are rigid, chemically resistant, and fire retardant. They offer good electrical insulation properties and are lightweight. | PVC sheets are widely used in construction, signage, and healthcare industries for applications such as cladding, advertising boards, and medical equipment. |

PP Sheets | PP sheets are lightweight, flexible, and offer excellent chemical resistance. They are also moisture-resistant and recyclable. | PP sheets find applications in packaging, automotive, and medical industries for products such as containers, interior components, and medical devices. |

|

TPO Sheets

|

TPO sheets are flexible, weather-resistant, and recyclable. They offer excellent durability and UV resistance.

|

TPO sheets are commonly used in automotive, roofing, and outdoor applications for components such as bumper covers, roofing membranes, and signage.

|

|

Characteristics

|

Comparative Analysis

|

|

Impact Resistance

|

ABS sheets excel in impact resistance, making them suitable for applications requiring protection against mechanical stress.

|

Chemical Resistance | HDPE and PVC sheets offer superior chemical resistance, making them ideal for applications involving exposure to corrosive substances. |

PVC Sheets | PVC sheets are widely used in construction, signage, and healthcare industries for applications such as cladding, advertising boards, and medical equipment. |

Flexibility | PP and TPO sheets exhibit flexibility, making them suitable for applications requiring bending or shaping. |

Weather Resistance | TPO sheets stand out for their weather resistance, making them ideal for outdoor applications where exposure to UV radiation and moisture is common. |

Recyclability | HDPE, PP, and TPO sheets are recyclable, offering environmentally friendly options for sustainable manufacturing practices. |

In conclusion, we have explored the diverse world of thermoplastic sheets, including ABS, HDPE, PVC, PP, and TPO, each offering unique properties and advantages suited to various applications. From ABS sheets' exceptional impact resistance to HDPE sheets' flexibility and chemical resistance, PVC sheets' rigidity and fire retardancy, PP sheets' lightweight and recyclability, to TPO sheets' weather resistance and durability, the range of options available provides manufacturers with versatile solutions for their specific needs.

We encourage readers to delve deeper into the versatility and applications of thermoplastic sheets to find solutions that best suit their requirements. Whether it's packaging, construction, automotive, healthcare, or outdoor applications, thermoplastic sheets offer a wide range of possibilities for innovation and efficiency. By understanding the properties and applications of each type of thermoplastic sheet, manufacturers can make informed decisions to enhance their products' performance, durability, and sustainability.

- Discover Endless Possibilities with Polyreflex Thermoplastic Sheets

- Reach Out Now!