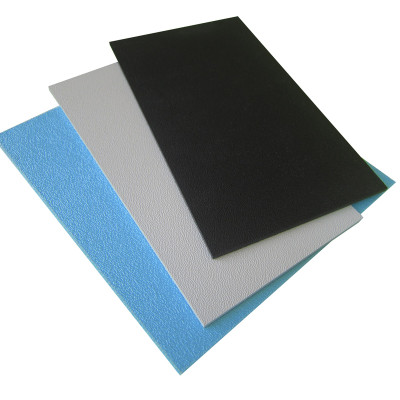

ABS

Acrylonitrile-Butadiene-Styrene, is the widely used engineering thermoplastic and is formed by the polymerization of styrene and acrylonitrile on the thermoplastic rubber which is then melt compounded with styrene acrylonitrile.

It is a polymer with the largest output and widest application scope, has made all properties of PS, SAN and BS dynamically integrated, which has excellent mechanical properties with harmony of toughness, hardness and rigidity.

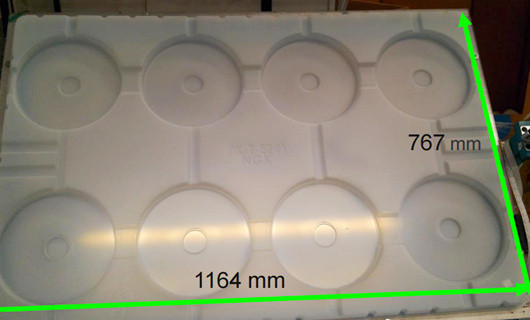

ABS panel can be laser or CNC cutting, and vacuum thermoforming, widely used in automotive interior and exterior, aircraft interior trims, lab equipment, luggage, office accessories, toys, machine parts and rollers.