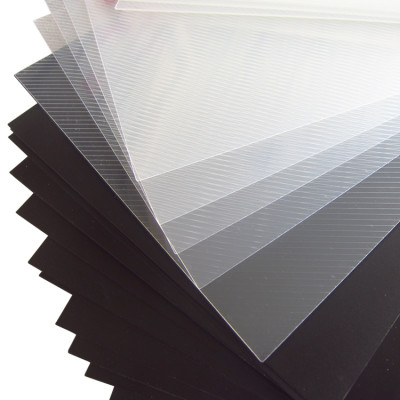

Polyreflex Polypropylene (PP) Film Sheet

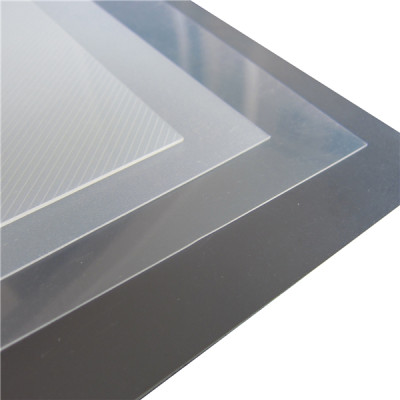

is a flexible and wear-resistant thermoplastic sheets or rolls, made of non-toxic, odorless polypropylene material through extrusion production.

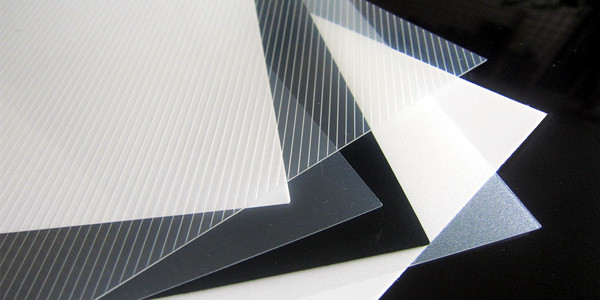

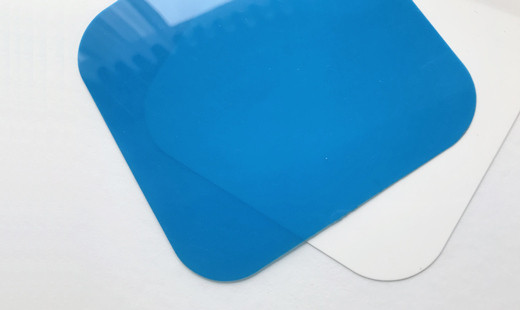

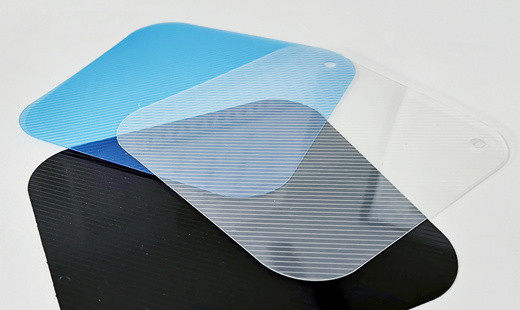

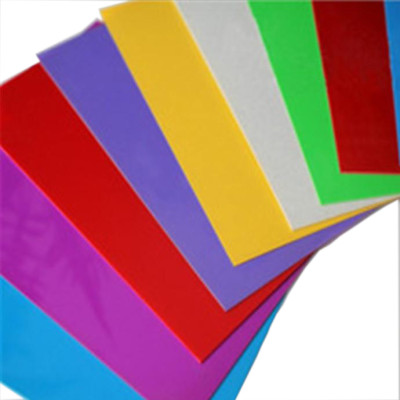

Polypropylene has great color fastness properties, which means that by adding color masterbatch and using textured pressure rollers, can produce the PP sheets with a variety of colors and surface textures, which can be applied to stationery products after die cutting or laser cutting.

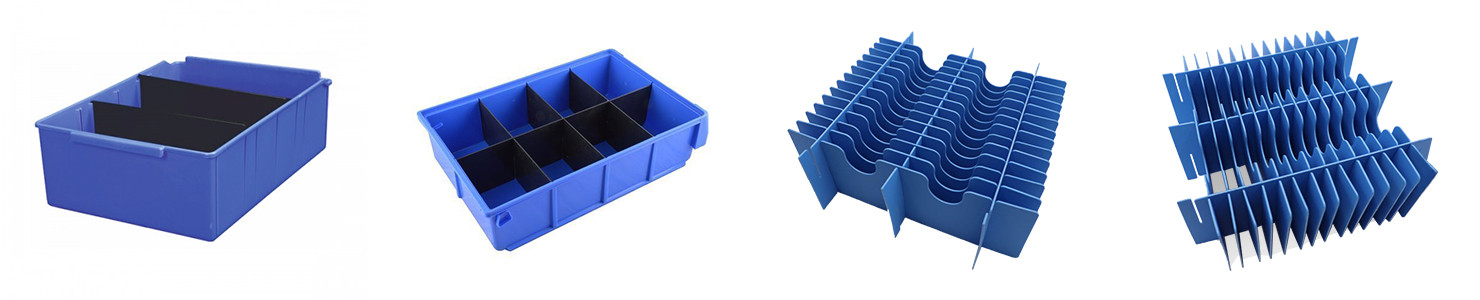

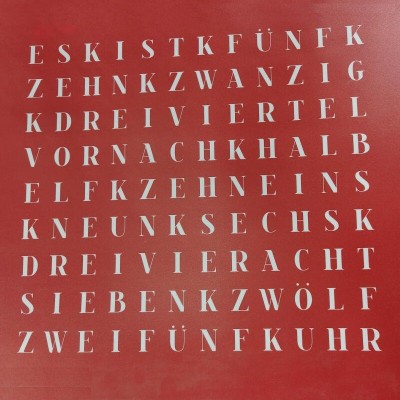

PP film sheet is highly processable, easy to offset printing, easy to fold into a box, and excellent molding ability, making it a popular packaging material in the food industry, cosmetics, toy, and electronics industry. Polypropylene has a very high melting point, and it is chemically resistant to most oils and solvents, this comes with many uses in the food container industry and other heat resistant applications.