Polyreflex Polypropylene (PP) Bubble Board

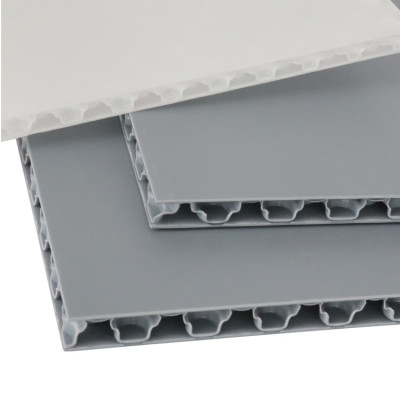

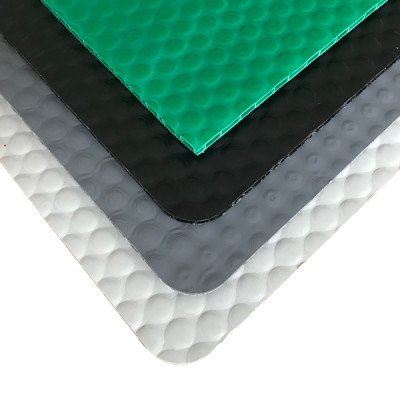

is a lightweight, durable material with a three-layer structure: two surface layers and a bubble core. Its unique "bubble" design—raised bubbles on one side and recessed bubbles on the other—provides flexibility, impact resistance, and cushioning.

This innovative structure makes PP bubble board ideal for a variety of applications, including automotive components, packaging and protective materials, providing excellent performance in demanding environments.

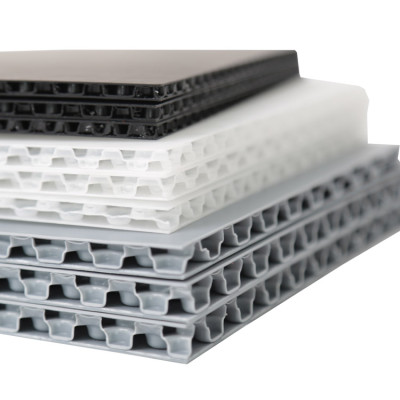

Eco-friendly and fully recyclable, PP bubble board supports sustainable practices. It can be easily customized with laminated surface materials to enhance its functionality, making it a versatile choice for numerous applications.