Polyreflex is a professional manufacturer with more than 15 years experiences, with five production sites located in China and one production site located in Vietnam.

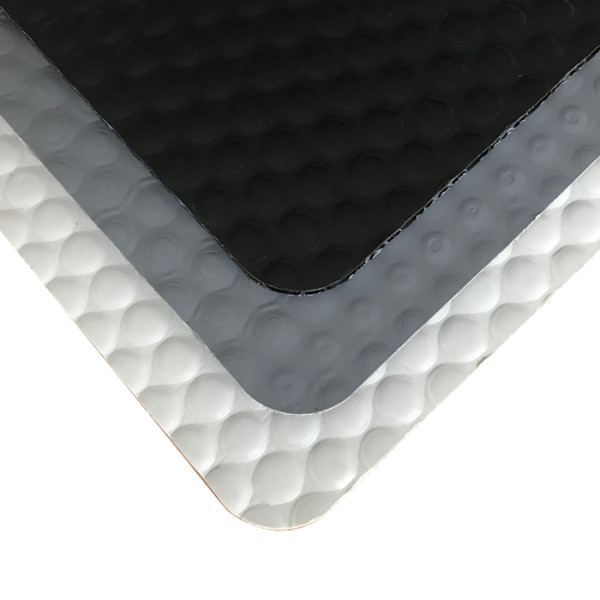

Custom Lightweight High Strength Plastic Polypropylene PP bubble board

Custom Lightweight High Strength Plastic Polypropylene PP bubble board

provide any custom work, like color, size, cut, seal

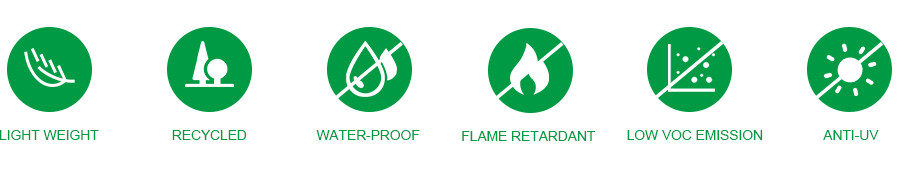

High impact

Flame retardant

Low VOC emission

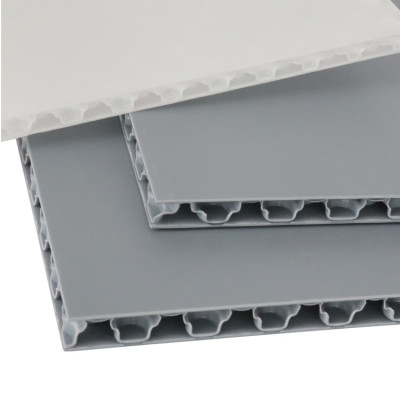

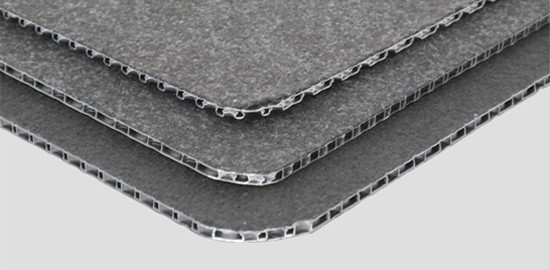

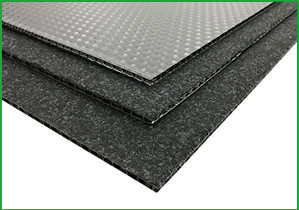

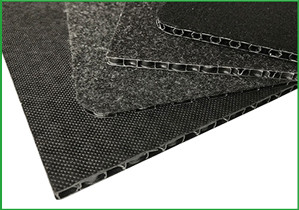

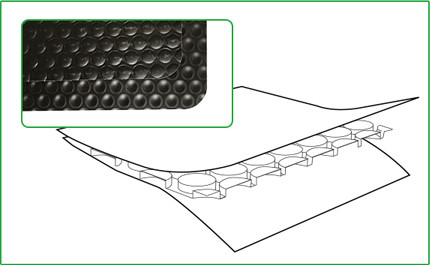

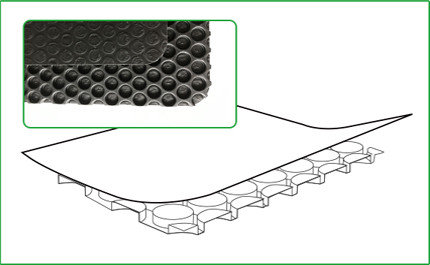

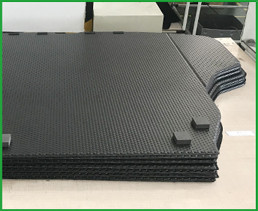

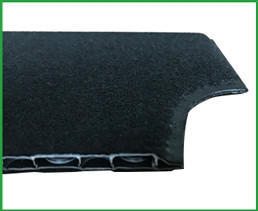

with a honeycomb structure inside and one/two flat surfaces with bubble

finish. It is Environment friendly, Flame retardant and durable.

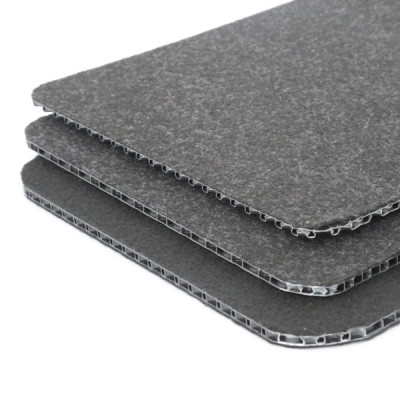

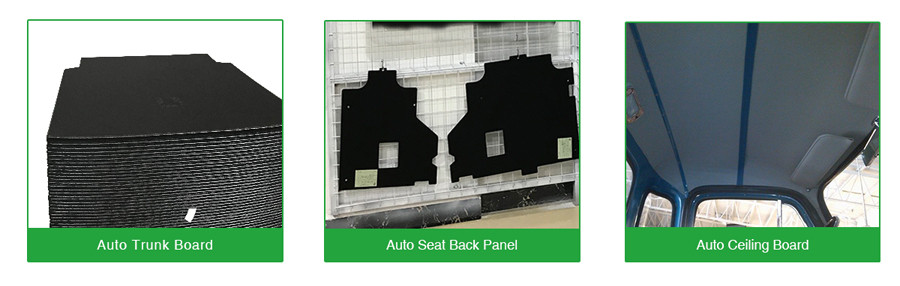

PP bubble board can be laminated with non-woven fabric. It is used as

spare wheel covers in the automobile luggage compartment, to achieve

the isolation function of spare tire and luggage compartment. It is also

used as luggage liner panel, seat back panel, side and roof panel of

mini-van, SUV, caravan etc.

It plays the role of body decoration, noise insulation, noise

reduction, load bearing and other.

- Light Weight – Approx. 50% Lighter Than Wood

- Numerous Options for Surface Finishing

- Dimension Stability and Waterproof

- Noise Insulation, Noise Reduction

- Excellent Compression Strength

- Corrosion and Rot Resistant

- Easy to Post Process

| Items | Modle | ||

| PP bubble board | PP bubble board with non-woven fabric | ||

| Thickness: | 3-11mm | 3-12mm | |

| Width: | Max. Width 1.5M. 900-1300mm are popular. Other width can be customized. | ||

| Size: | 1000x2000mm, 1200x2400mm, 1220x2440mm are standard. Other size can be customized. | ||

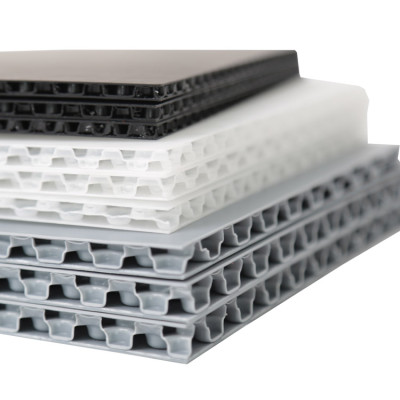

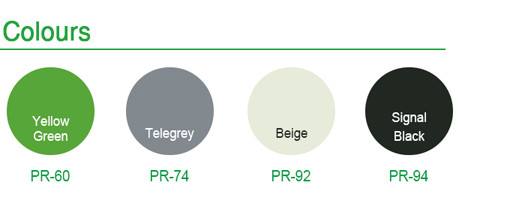

| Colour: | Black, gray, beige are available. Other colors can be customized according to RAL / Pantone. | Board | Black, gray, beige are available. Other colors can be customized according to RAL / Pantone. |

| Fabirc | Black, light black. | ||

| Weight: | 750-3800gsm. | Board | 750-3500gsm |

| Fabirc | 80-300gsm | ||

| Surface: | bubble surface | Single or double side for fabric lamination is available. | |

- Are you a trading company or a manufacturer?

- more>

- Can you cut to size or print or thermoform?

- more>

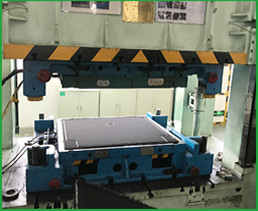

Of course we can. Polyreflex processing center has a variety of advanced processing equipment, and a well-trained and experienced technical team to meet the customized needs of customers, such as cutting, machining, vacuum forming, injection molding, blow molding, assembly, etc.

- What is the payment method?

- more>

T/T, L/C, PayPal, Western Union payment are available. Polyreflex is an Alibaba certified supplier, and it is also okay to place an order through Alibaba. https://polyreflex-cn.en.alibaba.com/

- What is the lead time?

- more>

Usually 15 to 20 days. The specific lead time is best to be confirmed after letting us know the order details. We have stock of plastic sheets to meet urgent needs, and we can also advance the delivery time for customers according to the production condition.

- Name

- *Title

- *Content

- Name:

- Helen G

- Tel:

0086-759-3320922

- Email:

- sale@polyreflex.com

- WhatsApp:

- https://wa.me/8613828266785

- Address:

- Shuilang Industrial Zone, Dalingshan Town, Dongguan, Guangdong, China