What is the ABS Plastic Sheet Manufacturing Process?

ABS (Acrylonitrile Butadiene Styrene) plastic sheets are renowned for their versatility, durability, and wide-ranging applications across industries. Composed of a blend of three different polymers – acrylonitrile, butadiene, and styrene – ABS sheets exhibit exceptional mechanical properties, including high impact resistance, thermal stability, and excellent aesthetic appeal. These characteristics make ABS sheets a popular choice in various sectors, including automotive, electronics, construction, and consumer goods.

Understanding the manufacturing process of ABS plastic sheets is crucial as it provides insight into how these sheets acquire their unique properties and characteristics. This knowledge empowers users to make informed decisions regarding material selection for specific applications and enables better quality control and optimization of production methods, ensuring consistent and reliable performance of ABS sheets in various environments. In essence, a comprehensive understanding of the manufacturing process sheds light on the intricacies of ABS plastic sheets, empowering users to harness their full potential in diverse applications, from product design to end-use performance.

Raw Materials and Preparation

ABS plastic sheet manufacturing begins with the careful selection and preparation of raw materials. The primary components of ABS resin include acrylonitrile, butadiene, and styrene, each contributing unique properties to the final product.

1. Introduction to Raw Materials

2. Importance of Material Quality and Consistency

The quality and consistency of raw materials are paramount in ABS sheet manufacturing. Variations in raw material composition can affect the mechanical, thermal, and aesthetic properties of the final product. Ensuring uniformity in material properties is essential to achieve consistent product performance and meet quality standards.

3. Overview of Material Preparation Steps

a. Blending: The raw materials, including acrylonitrile, butadiene, and styrene, are blended together in precise proportions to achieve the desired properties in the final ABS resin.

b. Compounding: The blended raw materials undergo compounding, where they are mixed and processed to achieve uniform distribution and dispersion of additives and reinforcements.

c. Additives: Various additives, such as stabilizers, plasticizers, and colorants, may be incorporated during compounding to enhance specific properties or meet application requirements.

d. Reinforcements: In some cases, reinforcing materials such as glass fibers or fillers may be added to improve mechanical strength, dimensional stability, or flame resistance of ABS sheets.

The meticulous preparation of raw materials is crucial to ensure the quality, consistency, and performance of ABS plastic sheets. By carefully selecting and blending raw materials and incorporating necessary additives and reinforcements, manufacturers can produce ABS sheets with tailored properties to suit a wide range of applications in industries such as automotive, electronics, appliances, and consumer goods.

Extrusion Process

The extrusion process is a fundamental step in the manufacturing of ABS plastic sheets, where the ABS resin is transformed into continuous sheets of uniform thickness and dimensions. This process involves several key stages and requires precise control of temperature, pressure, and material flow to achieve desired sheet properties.

1. Feeding and Melting: The ABS resin pellets are fed into the extruder hopper, where they are gradually heated and conveyed towards the extrusion barrel. Inside the barrel, the resin pellets are subjected to increasing temperature and pressure, causing them to melt and form a viscous molten mass.

2. Screw Extrusion: Within the extruder barrel, a rotating screw mechanism helps to transport and compress the molten ABS resin along the barrel's length. The screw's design and rotation generate shear forces that further homogenize the molten resin, ensuring uniformity in temperature and composition.

3. Die Design and Sheet Formation: As the molten ABS resin reaches the end of the extruder barrel, it passes through a specially designed die. The die imparts the desired shape and dimensions to the molten resin, forming it into a continuous sheet of uniform thickness. The die's configuration can vary depending on the intended application and desired sheet properties, allowing for customization of sheet thickness, width, and surface texture.

4. Cooling and Solidification: After exiting the die, the freshly extruded ABS sheet undergoes rapid cooling to solidify its shape and structure. Cooling methods may include contact cooling via rollers or water-cooled calibrators, as well as air or vacuum cooling systems. Proper cooling is essential to prevent deformation, warping, or internal stresses in the finished ABS sheet.

4. Cooling and Solidification: After exiting the die, the freshly extruded ABS sheet undergoes rapid cooling to solidify its shape and structure. Cooling methods may include contact cooling via rollers or water-cooled calibrators, as well as air or vacuum cooling systems. Proper cooling is essential to prevent deformation, warping, or internal stresses in the finished ABS sheet.

5. Temperature Control and Melt Flow: Temperature control is critical throughout the extrusion process to ensure optimal material flow and sheet quality. Precise temperature control helps to maintain the ABS resin's viscosity within the desired range, facilitating uniform extrusion and sheet formation. Monitoring and adjusting melt flow characteristics are essential to prevent defects such as melt fracture, uneven thickness, or surface irregularities in the finished ABS sheet.

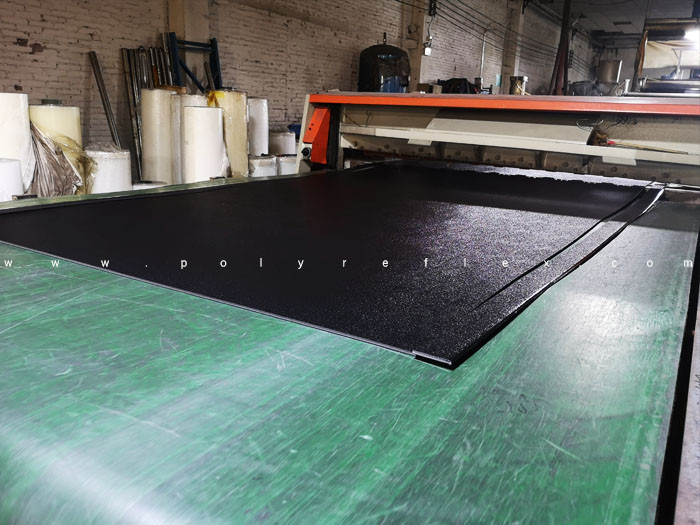

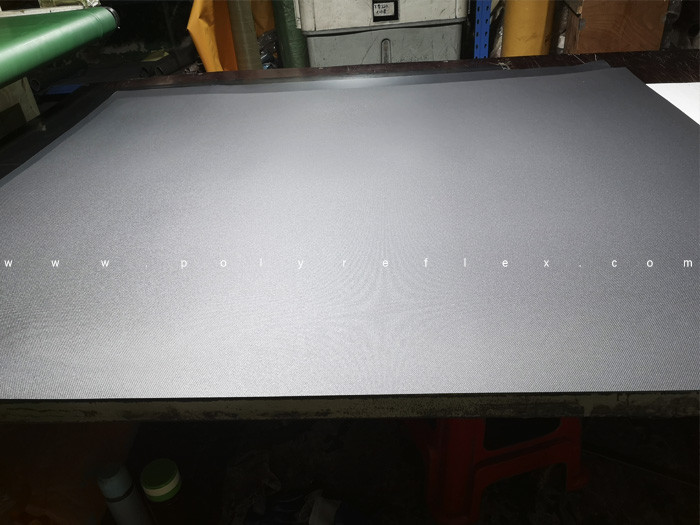

ABS Sheets Extrusion Production Line

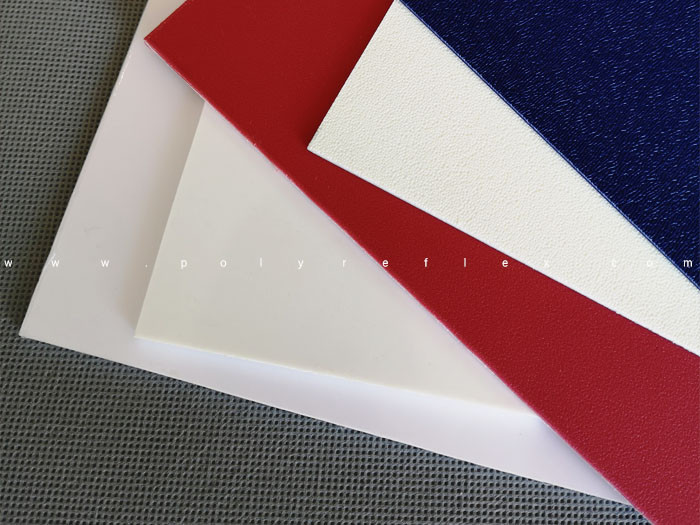

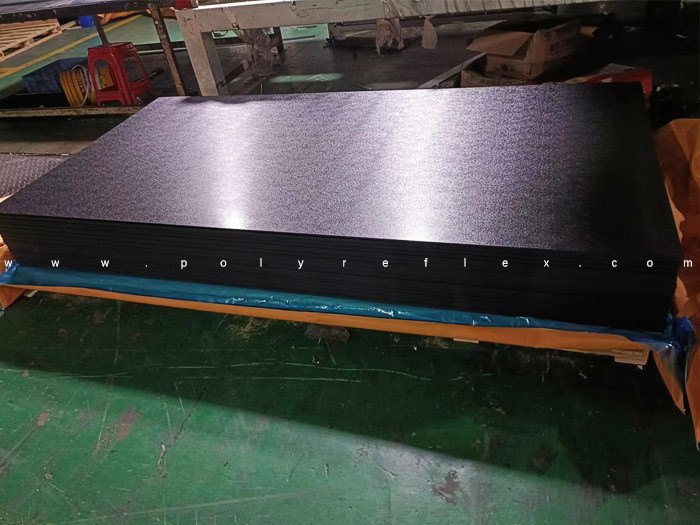

ABS Sheets Extrusion Finished Product

The extrusion process plays a pivotal role in shaping the properties and characteristics of ABS plastic sheets. By controlling key parameters such as temperature, pressure, and material flow, manufacturers can produce ABS sheets with tailored properties to meet specific application requirements. From automotive components to consumer electronics, extruded ABS sheets offer versatility, durability, and performance across a wide range of industries and applications.

Surface Treatment and Finishing

Surface treatment and finishing are crucial steps in the manufacturing process of ABS plastic sheets, as they enhance the appearance, functionality, and performance of the final product. Various techniques and methods are employed to achieve desired surface characteristics and meet specific application requirements.

1. Surface Treatment Methods:

2. Finishing Techniques:

3. Importance of Surface Quality:

In conclusion, surface treatment and finishing play a vital role in enhancing the appearance, functionality, and performance of ABS plastic sheets. By employing appropriate surface treatment methods and finishing techniques, manufacturers can customize ABS sheets to meet specific application requirements and deliver superior quality products to customers. Whether for aesthetic appeal, functional performance, or assembly compatibility, surface quality is a key consideration in the design and production of ABS sheets for various industrial and commercial applications.

Quality Control and Testing

Quality control and testing are essential aspects of the manufacturing process for ABS plastic sheets. These measures ensure that the final products meet specified standards for performance, durability, and consistency. Throughout the manufacturing process, various quality control measures are implemented to monitor and maintain product quality at every stage.

1. Quality Control Measures:

Quality control throughout the manufacturing process of ABS plastic sheets is comprehensive and meticulous. It begins with the careful selection and inspection of raw materials, ensuring consistent quality and purity. Strict adherence to formulation recipes and process parameters is enforced during material preparation, blending, and compounding stages to achieve uniform material properties. Process monitoring systems track key parameters such as temperature, pressure, and material flow rates, triggering immediate corrective actions to maintain product consistency. Visual inspections are conducted at various stages to identify defects, with automated inspection systems used for higher accuracy and efficiency.

2. Testing Methods for ABS Sheet Properties:

ABS sheets undergo rigorous testing post-manufacturing to assess various mechanical, thermal, and physical properties. Mechanical attributes like tensile strength, flexural strength, and impact resistance are evaluated using standardized methods such as ASTM D638, D790, and D256, respectively. Thermal properties such as heat deflection temperature and coefficient of thermal expansion are determined through techniques like differential scanning calorimetry (DSC) and thermomechanical analysis (TMA). Additionally, specialized instruments and visual inspection methods are employed to measure physical properties like surface roughness, gloss, and color.

3. Importance of Product Consistency and Performance:

Ensuring product consistency is paramount to meeting customer expectations and upholding brand reputation. Consistent quality minimizes defects, rework, and complaints, fostering improved customer satisfaction and loyalty. Reliable performance is crucial for ABS sheets across diverse applications like automotive components, electronics, consumer goods, and construction materials. Through robust quality control measures and thorough testing, manufacturers can ensure ABS sheets meet stringent standards and deliver reliable performance in real-world scenarios.

In summary, quality control and testing are integral parts of the manufacturing process for ABS plastic sheets. By implementing stringent quality control measures and conducting comprehensive testing, manufacturers can ensure that ABS sheets meet specified standards for performance, durability, and consistency. This commitment to quality and reliability enables ABS sheets to excel in diverse applications across industries while maintaining customer trust and satisfaction.

Throughout this article, we have explored the intricacies of ABS sheet production, from raw material selection and preparation to extrusion, sheet formation, surface treatment, and quality control. Understanding the manufacturing process of ABS sheets is paramount for informed material selection, product design, and optimization of production methods.

The significance of the ABS plastic sheet manufacturing process cannot be overstated, as it directly influences product quality, durability, and functionality. As such, we encourage readers to delve deeper into the world of ABS sheets and explore their myriad applications and benefits. Whether seeking impact-resistant automotive components, aesthetically pleasing consumer goods, or durable construction materials, ABS sheets offer versatility, reliability, and performance to meet a wide range of needs. Embrace the possibilities of ABS sheets for your specific requirements, and unlock the potential for innovation and success in your projects.

- Discover Endless Possibilities with Polyreflex ABS Sheets

- Reach Out Now!