How to Use PP Honeycomb Panel?

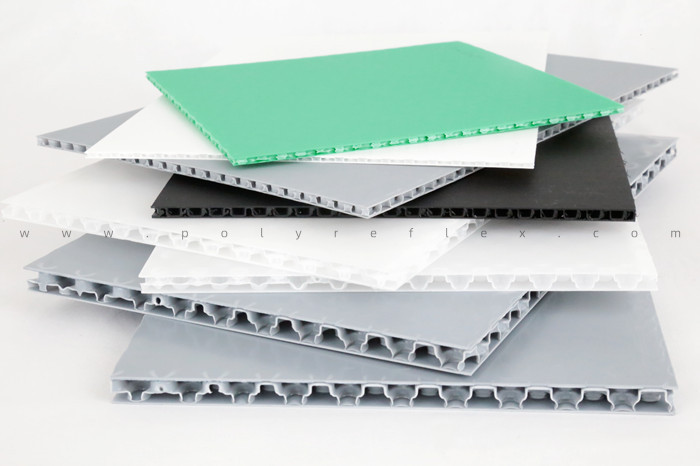

PP honeycomb panels are composite panels composed of a polypropylene (PP) honeycomb core sandwiched between two face sheets. The core structure resembles a honeycomb, with hexagonal cells that are interconnected, creating a strong and lightweight panel.

PP honeycomb panels offer numerous advantages that make them highly desirable for various industries and applications:

Lightweight

PP honeycomb panels are exceptionally lightweight, thanks to the hollow core structure. This property makes them ideal for applications where weight reduction is crucial, such as aerospace, automotive, and transportation industries.

High Strength

Despite their lightweight nature, PP honeycomb panels exhibit excellent strength and stiffness. The honeycomb structure provides optimal load distribution, making them capable of withstanding high compression and shear forces.

Impact Resistance

The honeycomb core structure of PP honeycomb panels absorbs and disperses impact energy, making them highly resistant to impacts and shocks. This property makes them suitable for protective packaging and applications where impact resistance is essential.

Chemical Resistance

PP honeycomb panels are resistant to various chemicals, solvents, and corrosive substances, which enhances their durability and lifespan.

To use PP honeycomb panels effectively:

Determine Requirements

Identify the specific requirements of your project, including load-bearing capacity, structural integrity, weight reduction goals, and environmental considerations.

Panel Selection

Choose the appropriate thickness, cell size, and face sheet material based on the application requirements and desired mechanical properties.

Design and Engineering

Collaborate with designers and engineers to integrate PP honeycomb panels effectively into your application, ensuring proper support and fastening methods.

Fabrication and Installation

Cut, shape, and join the panels using suitable methods such as adhesive bonding, mechanical fastening, or welding, as per the manufacturer's guidelines.

Surface Finishing

Apply surface finishes such as laminates, paints, or coatings to enhance aesthetics and provide additional protection against environmental factors.

Maintenance

Regularly clean and inspect the panels for any signs of damage or wear. Follow specific maintenance instructions provided by the manufacturer.

In summary, PP honeycomb panels are lightweight, strong, and versatile composite panels with a honeycomb core structure. They are used in a range of industries for applications that require lightweight yet high-strength materials, such as aerospace, automotive, marine, construction, and packaging. Proper panel selection, design, fabrication, and maintenance ensure their effective use in various applications.

POLYREFLEX HI-TECH has been a top manufacturer and supplier of PP sheet, PE sheet, ABS sheet, TPO sheet and other thermoplastic sheets in China since its establishment in 2006. We are committed to the development and manufacture of high quality plastic sheet, lightweight polypropylene sheets, including pp corrugated sheet, pp honeycomb board and pp bubble board. If you would like to know more about our products, or to get a quote, please feel free to contact us at sale@polyreflex.com or WhatsApp us at +8613828266785.