What Is the Difference Between PP Honeycomb Panels and PP Bubble Boards?

PP honeycomb panels and PP bubble boards are both types of lightweight and durable materials made of polypropylene, and have different applications in various industries. While they share some similarities, there are distinct differences between the two.

PP honeycomb panels are made using a honeycomb structure that consists of polypropylene (PP) core material sandwiched between two face sheets. The core material is typically arranged in a hexagonal pattern, resembling the structure of a beehive. This design gives the panel its exceptional strength-to-weight ratio.

Structure

PP honeycomb panels have a honeycomb core structure, which consists of a series of hollow cells. These cells are interconnected to form a strong and lightweight core.

Strength

The honeycomb structure provides excellent strength and rigidity to the panel. It can withstand high compression and shear forces while remaining relatively lightweight.

Weight

PP honeycomb panels are lightweight due to the hollow core structure. This property makes them suitable for applications where weight reduction is essential, such as aerospace, automotive, and transportation industries.

Applications

PP honeycomb panels find applications in various industries, including aerospace, automotive, marine, construction, furniture, and packaging. They are used for interior panels, partitions, flooring, doors, furniture components, and lightweight structures.

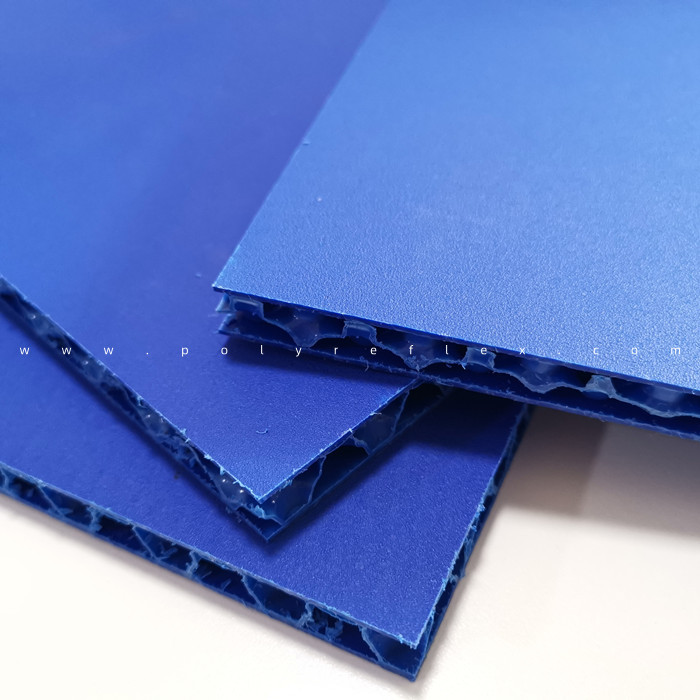

PP bubble boards, also known as PP bubble sheets or PP hollow sheets, are made from a flat sheet of polypropylene with hollow cylindrical structures, often referred to as bubbles, running through its thickness. These bubbles provide strength and insulation properties to the material.

Structure

PP bubble boards have a layered structure with hollow cylindrical bubbles running through the thickness of the sheet. The bubbles are evenly spaced and interconnected, providing structural integrity.

Insulation

The air-filled bubbles in PP bubble boards act as insulators, providing thermal insulation properties. This makes them suitable for applications where temperature control is necessary, such as packaging, advertising boards, and construction.

Flexibility

PP bubble boards are relatively flexible and can be easily cut, folded, or shaped to meet specific requirements. This flexibility allows for easy customization and installation.

Applications

PP bubble boards are commonly used in packaging, such as protective packaging, signage, advertising boards, and temporary structures. They are lightweight, cost-effective, and provide good impact resistance.

The main difference between PP honeycomb panels and PP bubble boards lies in their core structures. PP honeycomb panels have a hexagonal honeycomb core, providing high strength and lightweight properties.

On the other hand, PP bubble boards have a layered structure with hollow cylindrical bubbles, offering insulation and flexibility. The choice between the two depends on the specific requirements of the application, such as load-bearing capacity, insulation needs, and desired flexibility.

POLYREFLEX HI-TECH has been a top manufacturer and supplier of PP sheet, PE sheet, ABS sheet, TPO sheet and other thermoplastic sheets in China since its establishment in 2006. We are committed to the development and manufacture of high quality plastic sheet, lightweight polypropylene sheets, including pp corrugated sheet, pp honeycomb board and pp bubble board. If you would like to know more about our products, or to get a quote, please feel free to contact us at sale@polyreflex.com or WhatsApp us at +8613828266785.