How are HDPE sheets and UHMWPE sheets made?

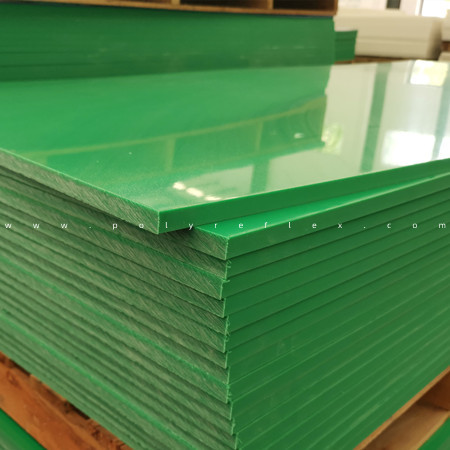

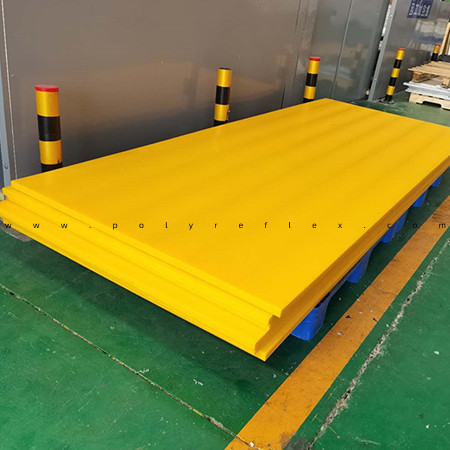

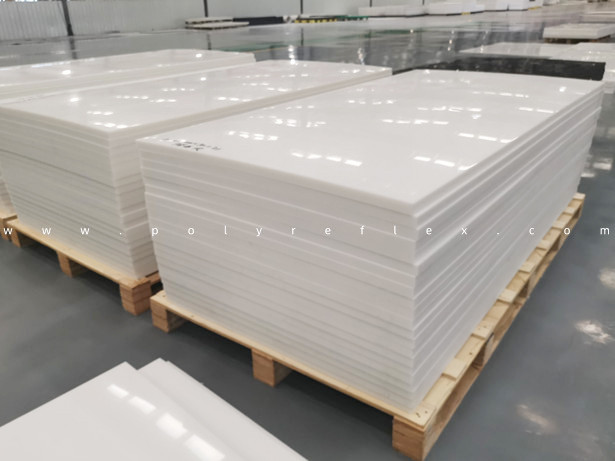

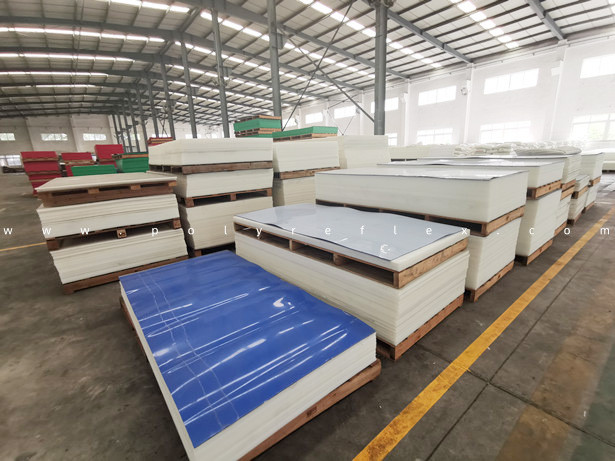

PE sheet refers to a thermoplastic sheet with polyethylene as the main raw material. We supply PE sheet types including LDPE sheet, HDPE sheet and UHMWPE sheet. PE sheet has the advantages of high toughness, excellent tensile strength, abrasion resistance, corrosion resistance, low temperature resistance, and high processability.

Both LDPE sheet and HDPE sheet are produced by extrusion process, while UHMWPE sheet is manufactured by compression molding process.

In this blog, we will share their manufacturing process through video.

Our HDPE sheet can be produced in a maximum width of 3 meters. The extrusion process means that its length is unlimited. You can customize the length of the board according to your needs. The thickness of HDPE sheets ranges from 0.4mm to 200mm. White and black are our most frequently produced colors, and its colors can also be customized.

The manufacturing process of UHMWPE sheet is to pour the powdered polyethylene raw material into the compression mold. Under high temperature and high pressure, the raw material is melted and fixed by a steel plate for several hours, and finally a flat board is formed. It can be known from this that the size of the UHMWPE sheet is determined by the size of the mold. We have multiple molds in different sizes, welcome to contact us for the producible size of UHMWPE sheet.

POLYREFLEX HI-TECH has been a top manufacturer and supplier of polypropylene sheets, polyethylene sheets and other thermoplastic sheets in China since its establishment in 2006. We are committed to the development and manufacture of lightweight polypropylene sheets, including pp corrugated sheet, pp honeycomb board and pp bubble board. If you would like to know more about our products, or to get a quote, please feel free to contact us at sale@polyreflex.com or WhatsApp us at +8613828266785.