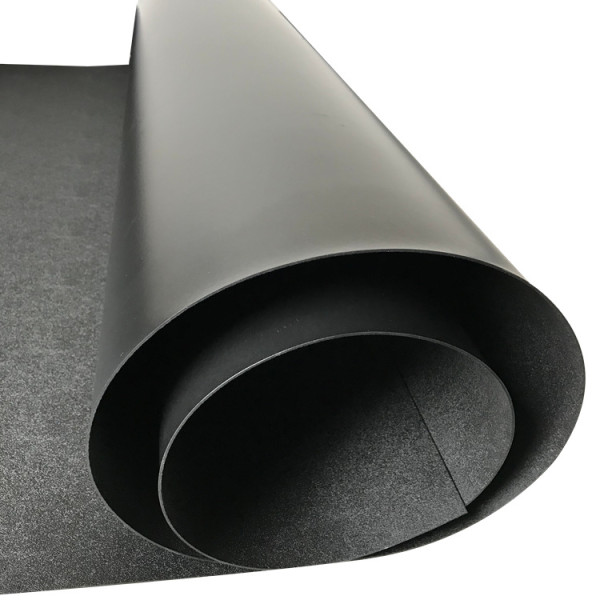

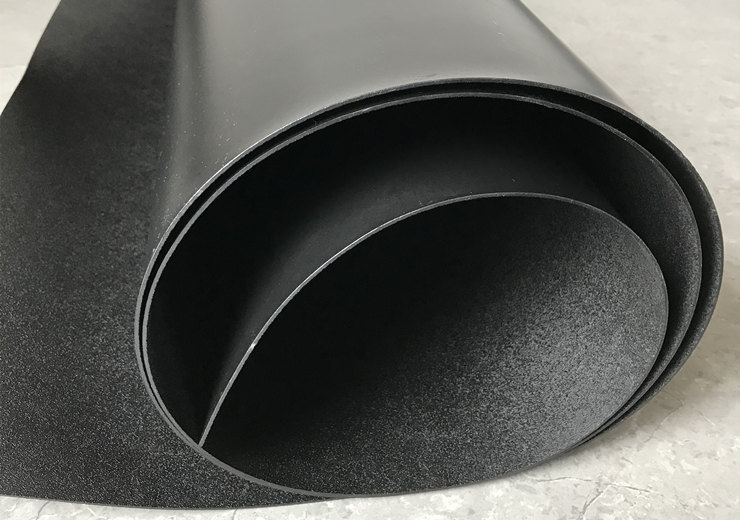

Polyreflex Thermoplastic Polyolefin (TPO) Sheets

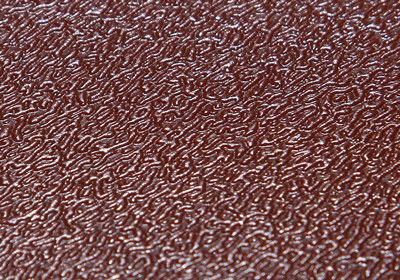

are high-performance materials made from a blend of polyolefin (PP or PE), rubber, and fillers like talc and carbon fiber. As part of the Thermoplastic Elastomer (TPE) family, TPO combines the benefits of both plastics and elastomers.

TPO sheets offer excellent hardness, impact resistance, and chemical resistance, making them ideal for a variety of industrial applications. They are also highly resistant to UV radiation and perform well in extreme temperatures, ensuring durability in outdoor environments.

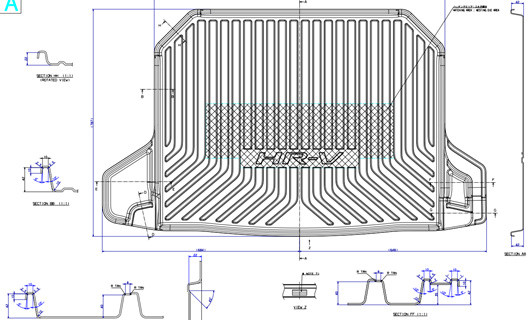

TPO sheets are commonly used in injection molding and thermoforming processes, providing reliable, long-lasting solutions for a range of applications, especially in the automotive industry, where they are used for parts that require durability.